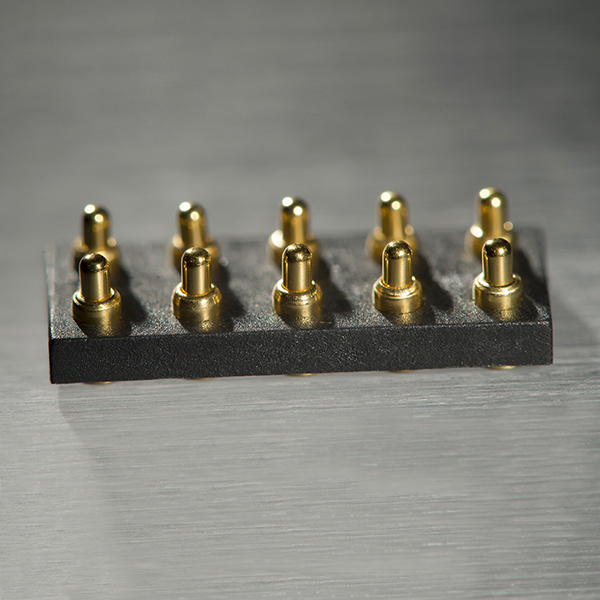

double row 10 pin pogo pin connector

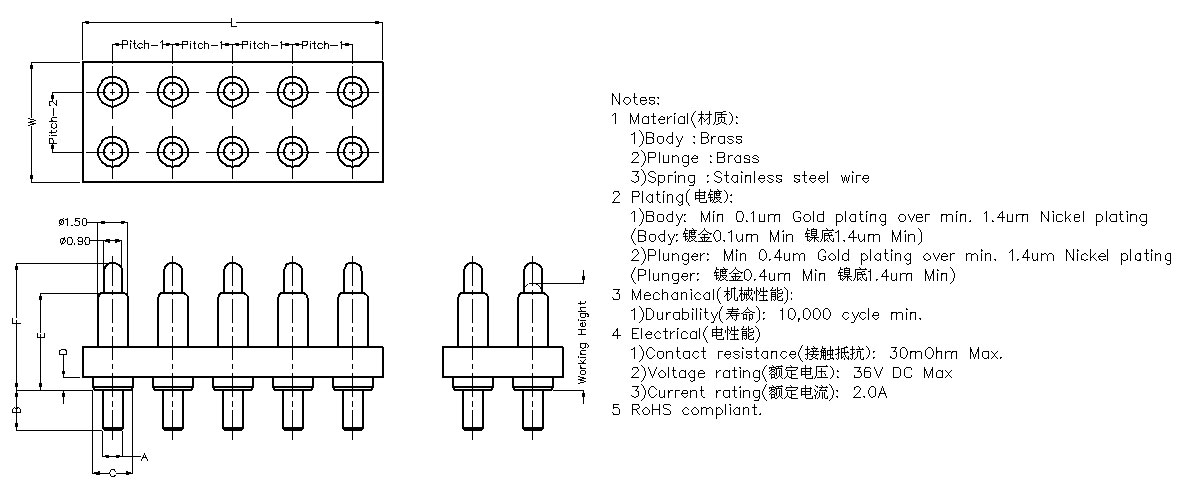

Housing: PPA, PA46, PA9T, LCP

Pogo Pin OEM

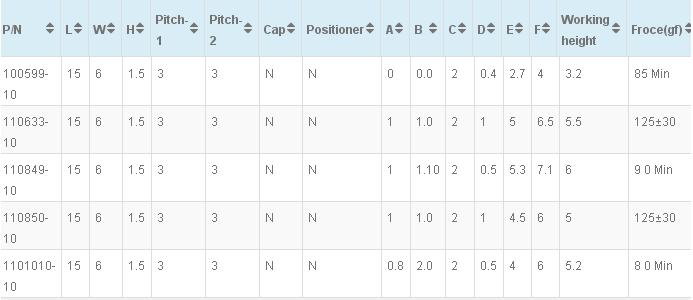

| Plastic Size(mm) | Pogo Pin Size(mm) | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| L | W | H | Pitch | Cap | Positioner | A | B | C | D | E | F | Number of Pin |

PACK:

Bulk: aluminum foil bag.

Reel: diameter Φ330mm; carrier tape width: 12, 16, 24, 32, 44mm.

=================================================================================

product testing introduction

| Electrical performance | ||||

|---|---|---|---|---|

| 1 | Contact impedance | 30 mohm Max at working stroke | Top-Link factory testing standard* | |

| 2 | Insulation Resistance | 500 Mohm Min | EIA-364-21 | |

| 3 | Dielectric Withstanding Voltage | No flash-over,air discharge,breakdown or leakage | EIA-364-20 | |

| 4 | Temperature Rise vs Current Rating | 30 °C Max. temperature rise at specified current |

EIA-364-70 | |

| Mechanical performance | ||||

| 1 | Spring force | refer to product drawing | EIA-364-04 | |

| 2 | Retention Force | 0.5Kgf(4.5N)Min. | EIA-364-29 | |

| 3 | Durability | 10,000 cycles Min. No physical damage Resistance after test 30 mohm Max. |

EIA-364-09 | |

| 4 | Vibration | No physical damage,No electrical discontinuity more than 1i second. | EIA-364-28 | |

| 5 | Mechanical Shock | No physical damage,No electrical discontinuity more than 1i second. | EIA-364-27 method A | |

| Environmental | ||||

| 1 | Solderability | solder coverage area Min.95% | EIA-364-52 | |

| 2 | Salt Spray Corrosion | No physical damage. Resistance after test 100 mohm Max. | EIA-364-26 condition B | |

| 3 | Resistance to Solder heat(IR/convection) | No cracks,chips,melting,orblister | EIA-364-56 | |

| 4 | Humidity | No physical damage, Resistance after test 100 mohm Max. | EIA-364-31,method ii,condition A | |

| 5 | Thermal Shock | No physical damage, Resistance after test 100 mohm Max. | EIA-364-32,method ii | |

| 6 | Temperature Life | No physical damage, Resistance after test 100 mohm Max. | EIA-364-17,condition A,condition 4 | |

| Environmental | ||||

| 1 | peel force | 10-130 gf | EIA-481 | |

| 2 | Drop Test | Refer to drop test Standard of Molex | ||

Remark: Considering the difference between test spot and actual work spot, the impedance test condition defined by Top-Link is based on the whole working stroke. This is what we generally said dynamic impedance testing, it differs from the static test condition of ELA-364923, the durability test standard is also based on this test condition.

———————————————————————————————————————————————————–

KLS is equipped with comprehensive inspection and reliability testing equipment.

KLS attaches great importance to quality management of each link, including IQC, IPQC, 100% dynamic testing of spring force and contact impedance , 100% appearance inspection, FQC sampling inspection, CQC, design verification, regular reliability testing, failure analysis, and so on.

KLS has implemented strict and effective quality control over each link which includes product design, sample preparation, trial production and mass production. As a consequence, our product quality is guaranteed.

==========================================================================================

pogo pin connector OEM type

1, small diameter, fine type products

The minimum can be done is below 0.75

2, high durability

Maximum durability of up to 1 million times

3, large current

Maximum up to 15A current

4, high reliability

100% dynamic impedance testing to ensure 100% functional zero defects

5, lower operating height

Minimum working height of up to 1.5mm, the chopping block can be lower

6, high precision (size & forward force)

Height tolerances up to +, – 0.05mm positive up to + / – 10%

7, non-standard structure

Customer requirements can be customized according to customer requirements, such as: mushroom head structure